Starting Your Own Business: What You Need to Know About Opening a Factory

Starting your own business and opening a factory is a dream for many. However, turning this dream into reality requires meticulous planning and choosing the right partners, such as a professional machine builder company offering comprehensive services. Machinery plays a crucial role in manufacturing operations, making the selection of equipment and its suppliers critical. Before beginning production, it is essential to prepare in every aspect—from planning and site selection to procuring the right machines to ensure smooth operations and high-quality products. This preparation also minimizes production errors, ensuring timely delivery of goods and services to customers.

Steps to Start Your Own Business

Starting a business, whether it’s a manufacturing plant or another type of operation, requires careful planning to ensure a smooth launch and long-term success. Key steps include:

Defining Your Concept and Business Plan

Identify Your Business Type: Determine the type of products or services you wish to produce or sell to set clear goals for your business.

Market Research and Customer Analysis: Analyze market demand, target customers, and competitors to evaluate the feasibility and opportunities in your chosen field.

Create a Business Plan: Outline production, management, marketing, and financial strategies to guide your operations and attract investors or secure funding.

Preparing Documents and Obtaining Permits

Business Registration: Choose a business structure (e.g., partnership, limited company, public company) and register it according to legal requirements.

Necessary Permits:

Factory Operation Permit

Construction Permit (if applicable)

Environmental Permits (for industries with potential environmental impacts)

Trademark Registration: To establish a unique brand identity and protect against imitation.

Financial Planning and Investment

Securing Funding: Explore funding options like personal savings, bank loans, venture capital, or government grants. Prepare a clear financial plan to attract investors or secure loans while ensuring you have enough resources to handle unexpected costs.

Budget Planning: Create a detailed budget covering all key expenses, including land rental, construction, machinery, and operational costs. A comprehensive budget helps manage finances effectively and avoids overspending.

Selecting the Location and Designing the Factory

Strategic Location: Choose a location with good transportation access, reliable infrastructure (electricity, water, drainage), and proximity to suppliers or target markets to reduce logistics costs and improve efficiency.

Factory Design: Design the factory layout to optimize production flow, ensure worker safety, and accommodate future scalability. Prioritize efficiency and compliance with industry standards.

Procuring and Installing Machinery

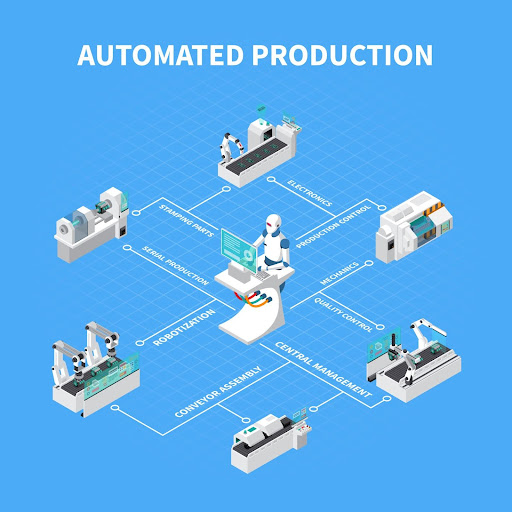

Choosing the Right Machines: Selecting the right machines ensures efficiency, consistency, and scalability in production. Automated and factory automation systems can reduce costs, enhance speed, and improve product quality. Advanced technologies like IoT-enabled systems offer real-time monitoring and remote management, helping minimize downtime and optimize performance.

Partnering with a Machine Builder Company: Collaborating with a reliable machine builder company simplifies the process of machine design, installation, and maintenance. Comprehensive services, including training and spare parts support, ensure your production runs smoothly, letting you focus on scaling your business with confidence.

Recruitment and Human Resource Development

Hiring Staff: A skilled workforce is essential for smooth factory operations. Focus on recruiting staff with relevant experience in machine operation, automation systems, and problem-solving to strengthen your team’s capabilities.

Training Programs: Regular training equips employees with the skills needed to efficiently handle advanced machinery and factory automation. Safety protocols, troubleshooting, and technology updates ensure improved productivity and reduced errors.

Establishing Management Systems

Production Management Systems: MES and ERP systems streamline production, offering real-time monitoring of inventory, machine performance, and schedules. These tools help optimize workflows, reduce waste, and maintain product quality.

Leveraging IoT Technology: IoT enhances production by enabling real-time communication between machines and systems. Alerts for maintenance and performance insights reduce downtime, while data analytics improve efficiency and decision-making.

Why Choosing a Machine Builder Company Is Key

Managing all aspects of setting up and running a factory can be overwhelming for new entrepreneurs. Partnering with a professional machine builder company can simplify operations by offering tailored solutions for automation, machinery manufacturing, and maintenance.

A reliable machine builder company provides:

Comprehensive services, from designing production systems to installing factory automation and machinery.

Expert consultation on production processes, machinery types, and system training.

Maintenance and spare parts support, ensuring long-term operational efficiency.

For entrepreneurs setting up a factory, Nippon Kikai is a trusted name in machine service, offering expert guidance, design, and installation of production systems. Their diverse range of machines and services ensures a seamless factory setup and optimized operations.

ราคา 365 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 13 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 294 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 113 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 548 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 136 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 759 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 279 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 181 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 345 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 128 บาท

🛒 สั่งซื้อสินค้าเลย!ราคา 490 บาท

🛒 สั่งซื้อสินค้าเลย!